Plastic Sneezeguards The Importance of Safety and Hygiene in the Workplace

The world has changed drastically over the past few years, and with it, the way we work and live. One of the most significant changes that have come about is the heightened emphasis on safety and hygiene in the workplace. With the outbreak of the COVID-19 pandemic, businesses around the world have been forced to take drastic measures to ensure the safety of their employees and customers.

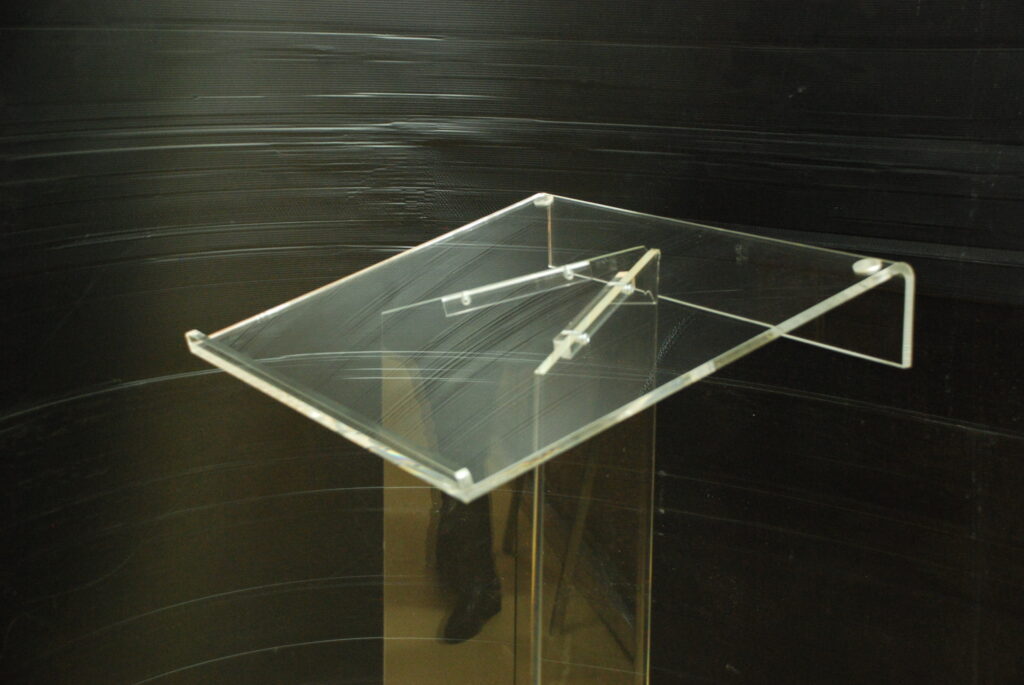

One of the most popular safety measures that businesses have adopted is the installation of Plastic Sneezeguards. These sneezeguards are essentially plastic barriers that are designed to prevent the spread of germs and viruses through coughing, sneezing, or talking. They are commonly used in restaurants, retail stores, and other public spaces where people are likely to interact closely with each other.

The Benefits of Plastic Sneezeguards

Plastic sneezeguards offer a range of benefits for businesses and their customers. Firstly, they provide a physical barrier that prevents the spread of germs and viruses from person to person. This is particularly important in indoor environments where the risk of transmission is higher.

Secondly, plastic sneezeguards are easy to clean and sanitize. Unlike other materials such as wood or metal, plastic is non-porous, which means that it does not absorb moisture or bacteria. This makes it easy to clean and disinfect, ensuring that the sneezeguard remains hygienic and effective at all times.

Finally, plastic sneezeguards are relatively inexpensive and easy to install. They can be custom-made to fit any space, and they are available in a range of sizes and styles to suit different needs.

Skylights: Enhancing Natural Light and Energy Efficiency

Another way that businesses can improve the safety and well-being of their employees is by improving the natural lighting in their workspace. Natural light has been shown to have a range of benefits for both physical and mental health, including increased productivity, reduced stress levels, and improved sleep quality.

One of the most effective ways to bring natural light into a building is by installing skylights. Skylights are essentially windows that are installed in the roof of a building, allowing natural light to enter from above. They are an excellent option for businesses that want to reduce their reliance on artificial lighting and improve their energy efficiency.

The Benefits of Skylights

Skylights offer a range of benefits for businesses and their employees. Firstly, they provide a natural source of light that is more pleasant and less harsh than artificial lighting. This can improve mood and productivity, as well as reduce eye strain and headaches.

Secondly, skylights can help to reduce energy costs by reducing the need for artificial lighting. This is particularly important in commercial buildings, which typically use a large amount of energy for lighting and HVAC systems.

Finally, skylights can enhance the overall aesthetic of a building, providing a unique and attractive feature that can help to attract customers and improve the overall impression of the business.

Moulding & Fabrication: Customized Solutions for Unique Spaces

Every business is unique, with its own set of challenges and requirements. This is particularly true when it comes to the design and layout of a workspace. In many cases, businesses require customized solutions that are tailored to their specific needs and preferences.

This is where moulding and fabrication come in. Moulding and fabrication are essentially the process of creating custom-made products from raw materials such as plastic, metal, or wood. This can include anything from custom fixtures and fittings to unique architectural features.

Moulding and fabrication are essential processes in manufacturing and construction industries. They involve shaping and forming materials into desired shapes, sizes, and designs. The benefits of moulding and fabrication are numerous, ranging from cost savings to improved product quality. In this article, we will discuss some of the advantages of these processes.

Customization

One of the most significant benefits of moulding and fabrication is the ability to customize products to meet specific needs. With these processes, manufacturers can produce products in different sizes, shapes, and designs. This flexibility allows them to cater to a wide range of customers with different requirements.

Customization is particularly essential in industries such as construction, where buildings and structures have unique requirements. With moulding and fabrication, builders can create customized components such as doors, windows, and trims to fit specific building designs.

Improved Product Quality

Moulding and fabrication processes are highly precise and can produce products with excellent dimensional accuracy. This accuracy ensures that the final products meet the required specifications, leading to improved product quality.

The precision of these processes also reduces the likelihood of errors and defects, leading to higher-quality products. Improved product quality results in reduced maintenance costs and fewer product recalls, leading to greater customer satisfaction.

Reduced Costs

Moulding and fabrication processes can significantly reduce production costs. For instance, by using these processes, manufacturers can create products in large quantities, reducing the cost per unit. Also, the precision of these processes reduces material waste, leading to cost savings.

In addition, moulding and fabrication processes can produce products in a shorter time, reducing labor costs. With these cost savings, manufacturers can offer their products at competitive prices, leading to increased customer demand.

Durable Products

Moulding and fabrication processes can produce products that are highly durable and long-lasting. For instance, manufacturers can use these processes to create components such as frames and beams that are strong and resistant to wear and tear.

In addition, these processes can create products that can withstand harsh weather conditions and other environmental factors, such as UV rays. The durability of these products ensures that they last longer, reducing the need for frequent repairs and replacements.

Versatility

Moulding and fabrication processes can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to create products with different properties, such as strength, durability, and flexibility.

For instance, in the automotive industry, moulding and fabrication processes are used to create various components such as body panels, dashboards, and steering wheels. These components are made from different materials such as aluminum, steel, and plastics, each with unique properties.

Environmental Benefits

Moulding and fabrication processes can have environmental benefits. For instance, these processes can reduce waste by producing products with high precision, leading to less material waste. Also, these processes can use recycled materials, reducing the need for raw materials and conserving natural resources.

In addition, some moulding and fabrication processes such as injection moulding and vacuum forming use less energy than traditional manufacturing processes, leading to reduced carbon emissions.

Conclusion

Moulding and Plastic fabrication Melbourne processes are essential in manufacturing and construction industries. These processes offer numerous benefits, such as improved product quality, reduced costs, and customization. They can also produce durable products, offer versatility, and have environmental benefits.

To take advantage of these benefits, manufacturers should consider incorporating moulding and fabrication processes into their production processes. This way, they can create high-quality products that meet specific customer needs while reducing production costs and conserving the environment.