Step-by-Step Guide to Ensuring Your Conveyor System is Safe

Introduction

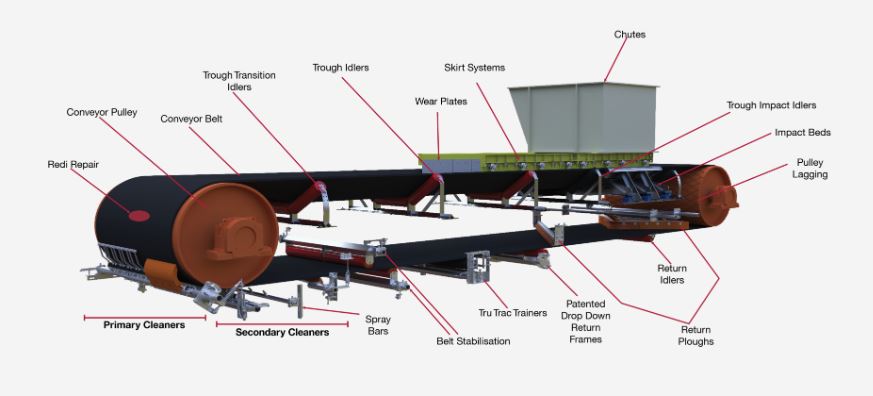

Conveyor Belt systems play a vital role in numerous industries, automating material handling processes and improving efficiency. However, it is crucial to prioritize safety when operating conveyor systems to prevent accidents and protect workers. In this step-by-step guide, we will outline essential measures to ensure your conveyor system is safe and compliant with industry standards.

Conduct a thorough risk assessment

Before implementing or modifying a conveyor system, it is essential to conduct a comprehensive risk assessment. Identify potential hazards such as pinch points, entrapment areas, and potential collisions. Evaluate the speed, load capacity, and functionality of the system to determine any risks associated with the specific operation. A thorough risk assessment will provide valuable insights and help establish preventive measures.

Install appropriate guarding

Guarding is a critical aspect of conveyor system safety. Install appropriate guards to prevent contact with moving parts, such as belts, pulleys, and rollers. Ensure all nip points and rotating components are adequately covered. Implement physical barriers or interlocked guards to restrict access to hazardous areas while still allowing maintenance and repair activities. Regularly inspect the guarding system to identify any damage or deterioration that may compromise safety.

Implement emergency stop systems

In case of a potential accident or emergency, it is crucial to have effective emergency stop systems in place. Install emergency stop buttons or pull cords at accessible locations along the conveyor system. Clearly mark and identify these emergency stop devices. Regularly test the emergency stop systems to ensure they are fully functional and easily accessible. Train employees on the proper use of emergency stop controls and familiarize them with emergency procedures.

Provide comprehensive training and signage

Ensure all employees operating or working near the conveyor system receive comprehensive training on safe operating procedures and potential hazards. Training should cover topics such as lockout/tagout procedures, emergency response protocols, and proper use of personal protective equipment (PPE). Display clear signage throughout the facility, indicating safety procedures, restricted areas, and potential hazards associated with the conveyor system. Regularly reinforce safety practices and provide refresher training as needed.

Regular maintenance and inspections

Establish a routine maintenance and inspection schedule for the conveyor system. Regularly inspect all components, including belts, pulleys, motors, and control panels, for signs of wear, damage, or malfunction. Lubricate moving parts as recommended by the manufacturer. Ensure proper tensioning and alignment of belts. Address any issues promptly to prevent breakdowns or safety hazards. Regular maintenance and inspections will help identify potential problems before they escalate.

Conclusion

Prioritizing safety when operating a conveyor system is crucial for protecting workers and preventing accidents. By following this step-by-step guide, conducting thorough risk assessments, implementing appropriate guarding, having emergency stop systems in place, providing comprehensive training, and ensuring regular maintenance and inspections, you can create a safe environment and optimize the efficiency of your Conveyor Belt system.