Sustainability with an Effective Conveyor Belt Cleaner

Power of an Efficient Conveyor Belt Cleaner

In the dynamic world of material handling and industrial processes, conveyor systems play a pivotal role in transporting goods and raw materials. To ensure seamless operations and maintain production efficiency, one crucial component often overlooked is the conveyor belt cleaner. This unassuming device holds the key to extending the lifespan of conveyor belts, reducing downtime, and enhancing overall sustainability.

Conveyor belt is the workhorses of industries, moving a wide array of materials across various distances. Over time, these belts accumulate debris, spillage, and material carryback, which not only hampers operational efficiency but also contributes to excessive wear and tear. This is where conveyor belt cleaners step in, acting as the first line of defense to prevent such issues.

One of the primary benefits of a conveyor belt cleaner is the reduction in maintenance downtime. Regular cleaning prevents material buildup, which can cause mistracking, slippage, and even belt damage. By consistently removing debris, the cleaner ensures that the conveyor system runs smoothly, minimizing the need for unscheduled maintenance and costly shutdowns.

In addition to maintenance, conveyor belt cleaners also enhance workplace safety. Accumulated debris on conveyor belts can lead to slip and fall hazards, posing risks to workers. By removing such debris, cleaners contribute to a safer working environment, reducing accidents and promoting employee well-being.

Sustainability is another key area where conveyor belt cleaners play a significant role. The accumulation of material carryback not only affects operational efficiency but also leads to material wastage. These materials, if not properly managed, can end up as environmental pollutants. By employing efficient belt cleaners, industries can minimize material loss, thereby reducing their ecological footprint and contributing to a more sustainable future.

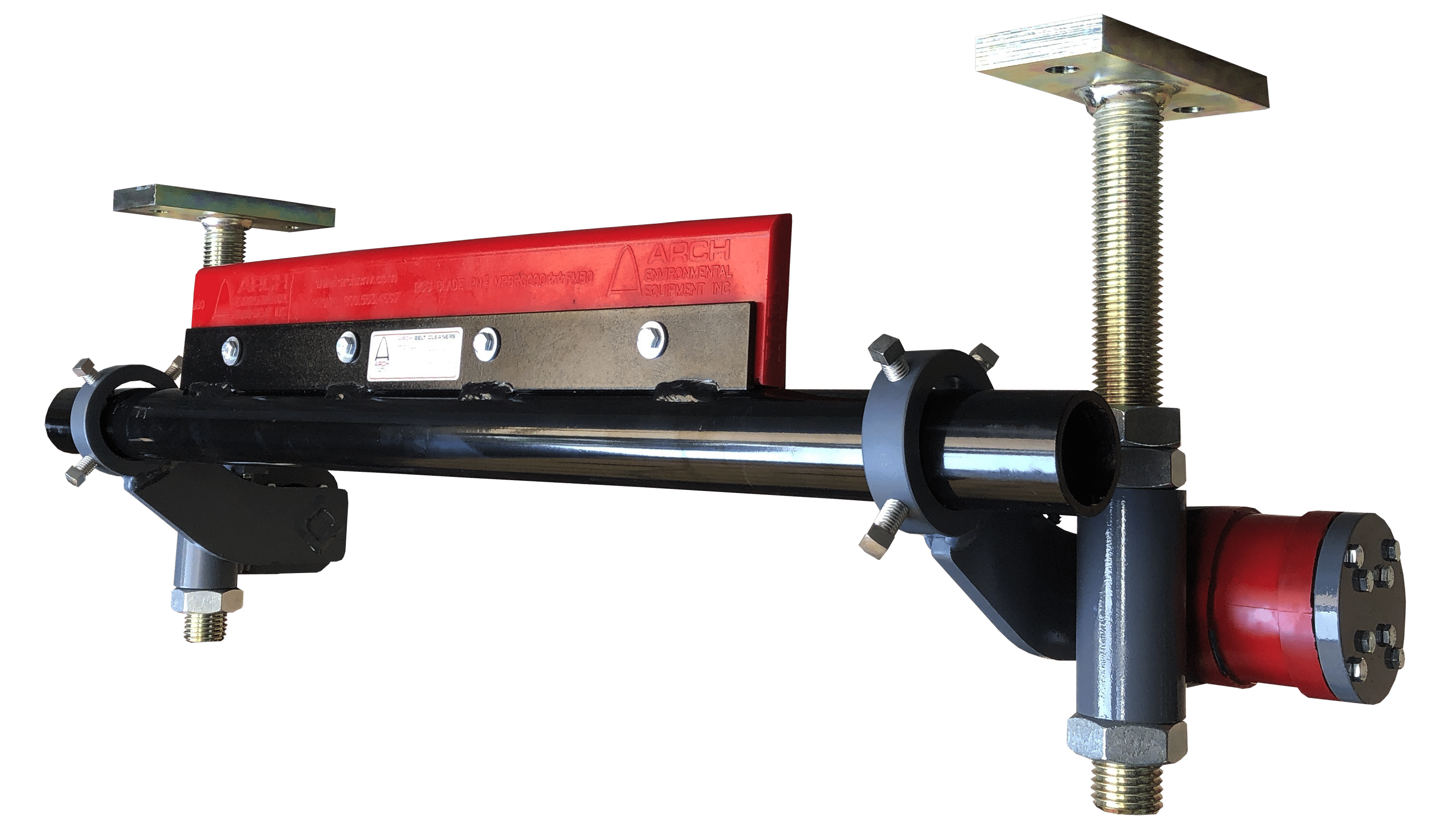

When selecting a conveyor belt cleaner, various factors come into play. The type of material being conveyed, the conveyor system’s speed, and the specific cleaning mechanism all influence the choice of cleaner. There are various types of cleaners available, including mechanical, scraper, and brush systems, each designed to address different cleaning challenges.

Regular maintenance and inspection of conveyor belt cleaners are crucial to ensure their continued effectiveness. Adjustments and replacements should be made as necessary to prevent deterioration in performance. By incorporating conveyor belt cleaner maintenance into routine schedules, industries can preserve the longevity of their conveyor systems and maximize return on investment.

In conclusion, the humble Conveyor Belt Cleaner holds the potential to revolutionize industrial processes. From boosting efficiency and reducing downtime to enhancing safety and sustainability, this unassuming device plays a pivotal role in material handling systems. As industries continue to evolve, investing in high-quality conveyor belt cleaners proves to be a strategic move that not only optimizes operations but also contributes to a greener and more productive future.